Oil & Gas

Professional Threading Solution

Expanded Line of Thread Turning and Thread Milling Solutions

For the Oil and Gas Industry

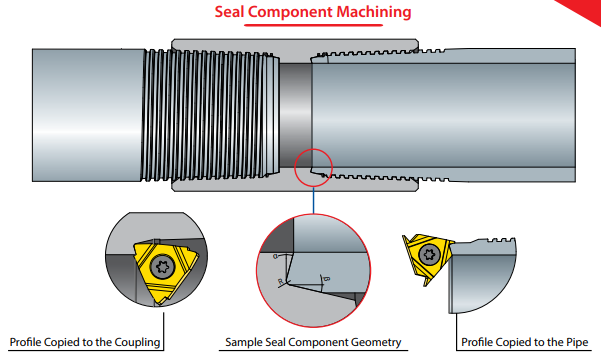

Solutions for Machining Seal Components in Premium Connections

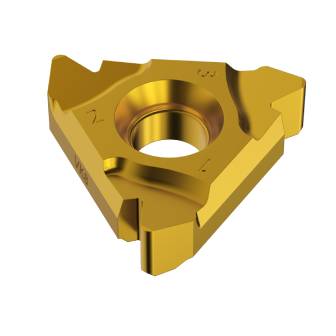

Vargus’ new high precision inserts for the Oil & Gas industry are specially designed to reproduce a variety of

different insert profile geometries accurately and consistently onto the component for optimized manufacturing of seal components.

* Quotations on tailor-made solutions are available upon receipt of the seal component geometry.

Advantages:

• High indexability of insert cutting edges: ± 0.02mm (± .0008”)

• Profile geometry can be tailored to specific applications

• Economical inserts with 3 cutting corners

• Insert profile is copied onto the component for significantly reduced machining cycle times

• Shorter set-up time

• Simple CNC programming

Solutions for Pipes and Couplings

Vardex's advanced threading solutions for the oil and gas

industry, now includes specialized solutions for tough and

challenging applications in the following insert profiles:

• APIRD

• Buttress

• Extreme Line

• VAM

• New VAM

• Hughes H-90

Solutions for Rotary Drill Stem Connections

Unique insert design with strengthened cutting edge and increased tool life for the

following Rotary Drill stem connections:

• NC - Number Connection

• REG - Regular Style

• FH - Full Hole

• IF - Internal Flash

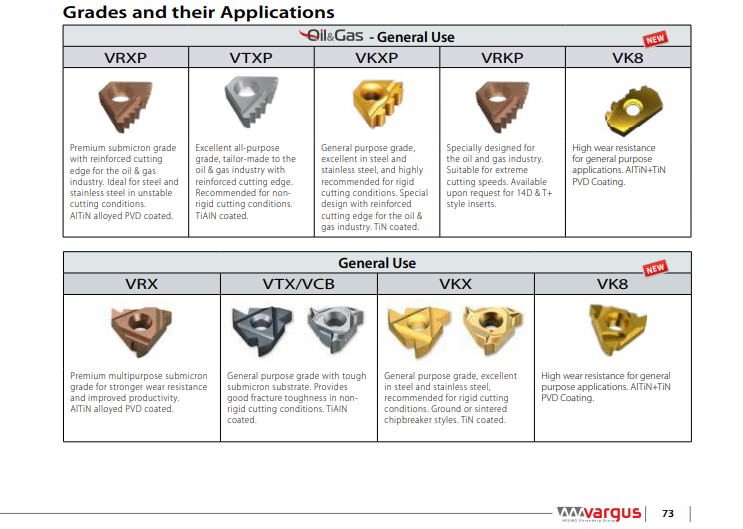

Grades and their Applications

Oil & Gas - General Use

VRXP

Premium submicron grade with reinforced cutting edge for the oil & gas industry. Ideal for steel and stainless steel in unstable cutting conditions.

AlTiN alloyed PVD coated.VTXP

Excellent all-purpose grade, tailor-made to the oil & gas industry with reinforced cutting edge.

Recommended for nonrigid cutting conditions. TiAIN coatedVKXP

General purpose grade, excellent in steel and

stainless steel, and highly recommended for rigid cutting conditions. Special design with reinforced cutting edge for the oil & gas industry. TiN coated.VRKP

Specially designed for the oil and gas industry.

Suitable for extreme cutting speeds. Available

upon request for 14D & T+ style inserts.

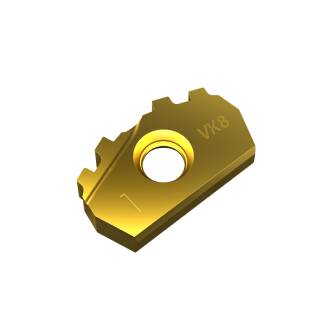

VK8

High wear resistance for general purpose

applications. AlTiN+TiN PVD Coating.

VRX

Premium multipurpose submicron grade for stronger wear resistance and improved productivity. AlTiN alloyed PVD coated.

VTX/VCB

General purpose grade with tough submicron substrate. Provides good fracture toughness in nonrigid cutting conditions. TiAIN coated.

VKX

General purpose grade, excellent in steel and stainless steel, recommended for rigid cutting

conditions. Ground or sintered chipbreaker styles. TiN coated.

VK8

High wear resistance for general purpose applications. AlTiN+TiN PVD Coating.